- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

- Lab & Measuring Tools

Brand: MICROACTIVE

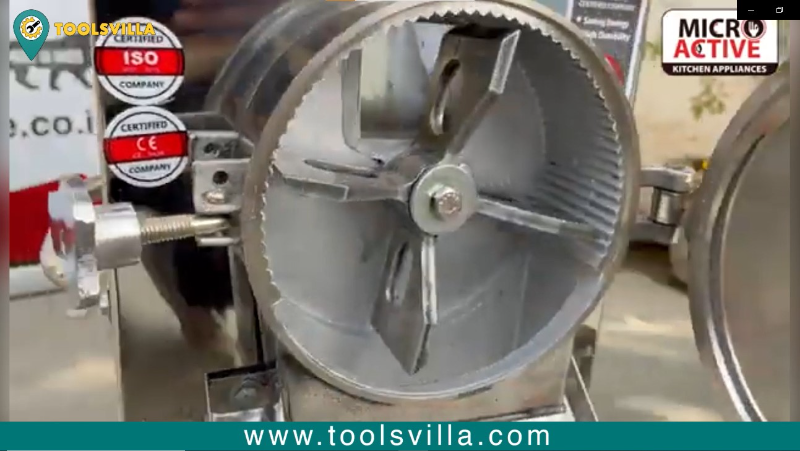

Microactive Premium Gravy Machine with 2HP Motor, For Smooth Gravies, Purees & Batter

SKU: TI-PG-40024

3 people have bought this recently

3 people have bought this recently  Estimated Delivery By: Mar 9 - Mar 11

Estimated Delivery By: Mar 9 - Mar 11

MRP : ₹20000 ₹16610

17% OFF!

3 people have bought this recently

3 people have bought this recently  Estimated Delivery By: Mar 9 - Mar 11

Estimated Delivery By: Mar 9 - Mar 11

Easy Return

& Refund

& Refund

Quality

Assurance

Assurance

Trusted

Delivery

Delivery

After Sales

Assistance

Assistance

Buyer

Protection

Protection

₹16610 (Including GST)

MRP : ₹20000

17% OFF!

Get Extra ₹249 OFF on Prepaid Orders

QTY :

-

1

+

Short Description

Premium Gravy Machine

Motor Power- 2HP

Country of origin: India

Specifications

- Brand: MICROACTIVE

- Weight (Approx.) : 35 kg

- Material : Stainless Steel

- Size- 19 inch * 26.5inch * 14inch (48.06 * 67.31 * 35.56 Cm)

- Chamber Size- 7 * 2.5 inches ( 17.78 * 6.35 Cm )

- Capacity- 30-40 kg/hr

Description

This Microactive Premium Gravy Machine with a 2HP motor is a specialized commercial-grade appliance designed for efficient and consistent preparation of smooth gravies, purees, pastes, and chutneys. It typically employs a high-speed grinding or blending mechanism to process large quantities of ingredients, ensuring a fine and uniform texture. The Premium designation suggests superior build quality, durability, and performance, making it an essential tool for high-volume food service establishments.

Features

:- High-Quality Construction: Often built with food-grade stainless steel (SS304 or SS316) for contact parts, ensuring hygiene, corrosion resistance, and longevity. The "Premium" aspect implies superior material and finish.

- Efficient Grinding/Blending: Designed with a powerful blade or grinding mechanism that ensures quick and uniform processing, yielding smooth and consistent gravies and pastes.

- Large Capacity (Implied): While not specified, a 2HP machine is typically built for commercial volumes, allowing for efficient batch processing.

- User-Friendly Controls: Features simple and intuitive controls for easy operation. May include safety interlocks, overload protection for the motor, and sturdy covers to ensure safe operation.

- Easy to Clean: Designed for quick disassembly of processing parts, allowing for thorough cleaning and maintenance to uphold hygiene standards.

- Low Noise & Vibration: Premium models often incorporate design elements to minimize operational noise and vibration for a better working environment.

- Durable Design: Built to withstand the rigors of commercial kitchen environments, ensuring long-term reliability.

Applications

:Restaurants & Hotels: Indispensable for preparing base gravies for curries, thick soups, sauces, and purees in large quantities, ensuring consistency and saving preparation time.

Catering Services: Used to efficiently produce a variety of pastes like ginger-garlic paste, onion paste, or tomato puree in bulk for catering events and large gatherings.

Sweet Shops & Snack Manufacturers: Employed for grinding ingredients for various Indian sweets, chutneys, and savory snack preparations, where fine, smooth textures are crucial.

Food Processing Units (Small to Medium Scale): Ideal for manufacturing units that produce packaged gravies, ready-to-cook pastes, or condiments, ensuring uniformity and quality control in their products.

Usage

:Preparation of Ingredients: Ensure all ingredients (e.g., onions, tomatoes, ginger, garlic, soaked nuts) are pre-chopped into manageable sizes as per the machine's recommendation to facilitate efficient grinding and prevent overloading.

Loading the Machine: Carefully load the prepared ingredients into the machine's processing chamber or hopper. Avoid overfilling, leaving enough space for proper circulation and blending.

Operation and Monitoring: Secure the lid and initiate the machine using the power switch. Monitor the grinding process, ensuring it runs smoothly. For very thick or fibrous ingredients, it may be beneficial to add a small amount of water or oil to aid in blending and achieve the desired consistency.

Achieving Desired Consistency: Allow the machine to run until the desired smoothness and consistency are achieved. This may vary based on the ingredients and the final product requirement. Stop the machine once the texture is satisfactory.

Unloading and Cleaning: Turn off the machine and carefully unload the processed gravy/paste. Immediately clean all contact parts with warm, soapy water to prevent food residue from drying and to maintain hygiene.

Select attribute