- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

- Lab & Measuring Tools

<

>

Brand: Generic ( Made in India )

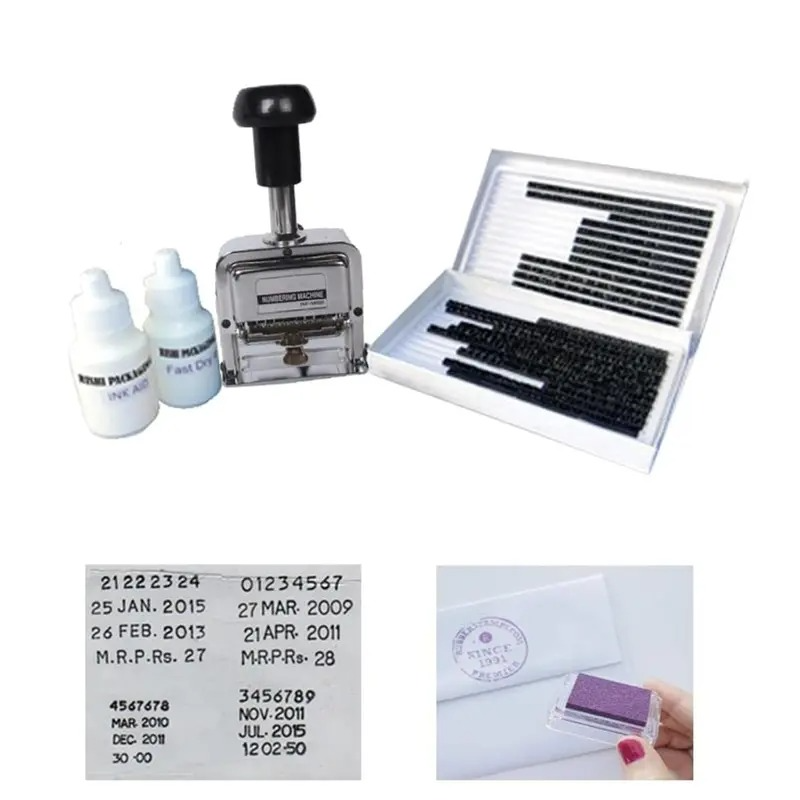

Manual 2mm Label Stamping Machine with Ink & Pad Softener

SKU: PH-SJ-20220135

202 people have bought this recently

202 people have bought this recently  Delivery By: Feb 18 - Feb 20

Delivery By: Feb 18 - Feb 20

MRP : ₹2999 ₹1979

34% OFF!

202 people have bought this recently

202 people have bought this recently  Delivery By: Feb 18 - Feb 20

Delivery By: Feb 18 - Feb 20

Easy Return

& Refund

& Refund

Quality

Assurance

Assurance

Trusted

Delivery

Delivery

After Sales

Assistance

Assistance

Buyer

Protection

Protection

₹1979 (Including GST)

MRP : ₹2999

34% OFF!

Get Extra ₹30 OFF on Prepaid Orders

QTY :

-

1

+

Short Description

This manual stainless steel code stamping machine efficiently imprints 2mm high letters and numbers onto various surfaces. The kit includes ink and pad softener, offering a durable and portable solution for low-volume manual coding tasks.

Country of origin: India

Specifications

- Brand: Generic ( Made in India )

- Weight (Approx.) : 0.9 kg

Description

This is a robust, hand-operated code stamping machine crafted from durable stainless steel. It is specifically designed for manually imprinting letters and numbers with a consistent height of 2mm onto various surfaces. The product is offered as a complete kit, including a 100ml bottle of ink and a 100ml bottle of pad softener, providing the essential consumables for immediate use. Its manual operation makes it a practical solution for low-volume marking needs where portability and ease of use are prioritized.

Features

:Accessories

:Applications

:This manual code stamping machine is well-suited for a range of low to medium volume marking tasks, including:

- Product Identification: Manually stamping identification codes or numbers onto manufactured goods.

- Date Coding: Imprinting manufacturing or expiry dates on products or packaging.

- Batch Numbering: Marking products with batch codes for traceability.

- Inventory Control: Applying codes to items for inventory management purposes.

- Small-Scale Labeling: Creating permanent markings on labels or tags.

- Workshops and Garages: For marking tools, parts, or other items for organization.

Usage

:Maintenance:

Maintaining this manual stamping machine is relatively straightforward:

- Ink Pad Management: Regularly re-ink the ink pad to ensure clear and legible impressions. Use the pad softener to maintain the pad's moisture level. Clean the pad periodically to remove any accumulated dried ink or debris that could affect print quality.

- Machine Cleaning: Wipe the stainless steel body of the machine with a clean, dry cloth to remove dust and fingerprints. For ink stains on the machine, use a mild, metal-safe solvent for cleaning.

- Lubrication (If Applicable): If the machine has moving parts, such as a character selection dial or hinges, apply a small amount of light machine oil periodically to ensure smooth operation and prevent stiffness.

- Storage: Store the machine in a clean, dry environment to prevent dust buildup. Keep the ink and softener bottles tightly sealed when not in use to prevent evaporation or spillag.

Precautionary Guidance:

Select attribute