- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

- Lab & Measuring Tools

Brand: Generic (Imported)

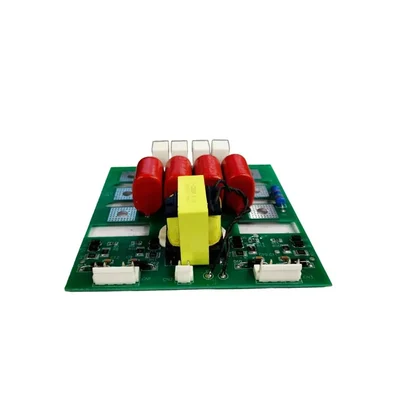

NG Weld 3 Phase Inverter Control Board for 400 amp Welding Machine (400 CI)

SKU: TI-NW-55299 Estimated Delivery By: Mar 4 - Mar 6

Estimated Delivery By: Mar 4 - Mar 6

MRP : ₹1999 ₹1750

12% OFF!

Estimated Delivery By: Mar 4 - Mar 6

Estimated Delivery By: Mar 4 - Mar 6

Easy Return

& Refund

& Refund

Quality

Assurance

Assurance

Trusted

Delivery

Delivery

After Sales

Assistance

Assistance

Buyer

Protection

Protection

₹1750 (Including GST)

MRP : ₹1999

12% OFF!

Get Extra ₹26 OFF on Prepaid Orders

QTY :

-

1

+

Short Description

400 amp PCB Control Board for IGBT Welding Machine

3-phase

Suitable for : 400 A MMA/DC Arc Welding Machine

Country of origin: China

Specifications

- Brand: Generic (Imported)

- Weight (Approx.) : 200 gm

- Model Number : 400CI (3-Phase)

- Compatibility : 400 A MMA/DC Arc Welding Machine

- Phase Support : Three-Phase (3Ph) Systems

- Control Logic : Precision PWM Current & Voltage Regulation

- PCB Grade : Industrial FR4 with High-Thermal Resistance

- Connectivity : Multi-Pin Easy-Plug Connectors

- Voltage : 380-415V

Description

The Arc 400 CI IGBT Card is the main inverter control board used in an industrial-grade 400 A MMA/DC arc welding machine employing IGBT (Insulated Gate Bipolar Transistor) inverter technology. This card forms the electronic core of the welding power source, taking AC mains input (typically 3-phase 380–415 V) and converting it into a high-frequency controlled DC output for welding. It enables precise control over welding current and arc characteristics and replaces traditional heavy transformer designs with compact, efficient inverter circuitry. IGBT cards support features such as arc stabilization, protective functions, and advanced welding modes, making the welding machine suitable for heavy-duty industrial and fabrication work.

Features

:- Advanced IGBT Inverter Technology Uses high-speed IGBT modules to convert AC to controlled DC welding output, improving energy efficiency and reducing weight compared with transformer-based machines.

- Stable & Adjustable Welding Output Allows adjustable welding current up to ~400 A with smooth, stable arc characteristics for various electrode types and material thicknesses

- Reduces open-circuit voltage when idle, improving operator safety (especially in damp environments).

- IGBT inverter technology, the unit is more portable and less bulky than traditional transformer-based welders, making handling and transport easier

Applications

:- Industrial MIG Welders : Main control unit for wire feed and voltage management.

- Heavy-Duty MMA Machines : Reliable current regulation for stick welding.

- Workshop Upgrades : Replacing old or faulty 400X series control boards.

- Automation Systems : Suitable for integrated 3-phase industrial welding setups.

Usage

:Usage Guidance :

- Power Down : Completely disconnect the 3-phase power supply before opening the machine.

- Mapping : Take a photo of existing wire connections on the old card before removal.

- Installation : Align the card on the mounting standoffs and secure it firmly.

- Wiring : Reconnect all multi-pin plugs ensuring they are fully seated and locked.

- Calibration : Perform a low-current test run to verify arc stability before full-load operation.

Maintenance Guidance :

- Cleanliness : Use dry air to remove metallic dust buildup, which can cause short circuits on the PCB.

- Terminal Check : Inspect connector pins periodically for signs of carbon soot or loose seating.

- Thermal Management : Ensure the machine’s internal cooling fans are functioning to prevent card overheating.

Select attribute