- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

- Lab & Measuring Tools

Brand: Generic ( Made in India )

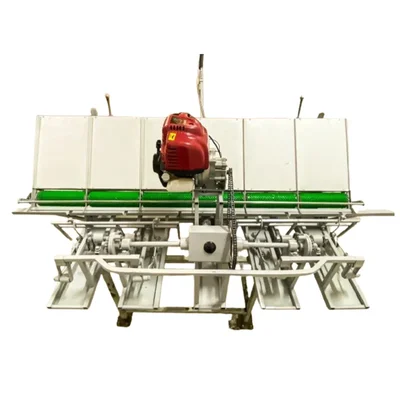

Stainless Steel Automatic 6-Row Walking Type Rice Transplanter by 4-Stroke Petrol Engine with 120/min Planting Frequency

SKU: SI-6R-20227

12 people have bought this recently

12 people have bought this recently  Delivery By: Feb 8 - Feb 10

Delivery By: Feb 8 - Feb 10

MRP : ₹150000 ₹116400

22% OFF!

12 people have bought this recently

12 people have bought this recently  Delivery By: Feb 8 - Feb 10

Delivery By: Feb 8 - Feb 10

Easy Return

& Refund

& Refund

Quality

Assurance

Assurance

Trusted

Delivery

Delivery

After Sales

Assistance

Assistance

Buyer

Protection

Protection

₹116400 (Including GST)

MRP : ₹150000

22% OFF!

Get Extra ₹1,746 OFF on Prepaid Orders

QTY :

-

1

+

Short Description

6 Row Engine Operated Rice Transplanter

4 - Stroke Engine

Walking Type

Country of origin: India

Specifications

- Brand: Generic ( Made in India )

- Material : Stainless Steel

- Height : 2 feet

- Weight (Approx.) : 196 kg

- Power Source : Engine

- Engine Type : 4 Stroke

- Engine Capacity : 35 cc

- Body Material : Stainless Steel

- Row Space : 250-300 mm

- Planting Frequency : 120/min

- Tray Size : Height 13 Inches (33.02cm), Length 37 Inches(93.98cm), Width 1 Inches(2.54cm)

- Fuel Used : Petrol

- Fuel Consumption : 750-900 ml in 1 hour

- Usage/Application : Agriculture, Farming

- Weight : 95 Kg (Approx.)

Description

A 6 Row Engine Operated Rice Transplanter is a specialized agricultural machine used to efficiently plant rice seedlings in rows in the field. This type of transplanter can plant 6 rows of seedlings at the same time, resulting in faster and more productive planting than manual methods. It help farmers save money on labor while also addressing labor shortages. The machine has multiple parts, including a power source it is powered by 4 Stroke Engine, A Seedling Tray, A Planting Mechanism, and A Drive System. The transplanter is moved over the field by the driving system, which also regulates the seedlings' depth and spacing. Using a rice transplanter is a popular option for rice farmers because it has 4-stroke engine which result in higher yields, more efficiency, and lower labor costs.

Features

:- Time saving : It can transplant several seedlings at once, thereby reducing the time and effort required for the entire process.

- Uniformity : It ensures that the seedlings are uniformly spaced and planted at the same depth, which can lead to better plant growth and yield.

- Increased efficiency : It can help farmers cover more area in less time.

- Labor saving : It can significantly reduce the number of laborers required to complete the task, thereby reducing labor costs.

- Reduced plant damage : It reduces the risk of plant damage and ensures that the seedlings are planted with minimal disruption to their roots.

Usage

:Operating the Transplanter :

- Start the Engine : Follow proper starting procedures, this involves turning on fuel valves, and pulling the starter cord.

Begin Transplanting :

- Position yourself comfortably behind the machine.

- Gradually engage forward motion using throttle control while ensuring that seedlings are being transplanted correctly into prepared fields.

- Maintain a steady pace, too fast can lead to uneven planting while too slow may cause clumping of seedlings.

Monitoring During Operation :

- Watch for Clogs or Malfunctions : Continuously monitor for any signs of clogging in seedling trays or malfunction in transplanting mechanisms.

- Adjust Speed as Necessary : Depending on field conditions (e.g., soil type and moisture), you may need to adjust your speed during operation to ensure proper planting depth and spacing.

Select attribute