- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

- Lab & Measuring Tools

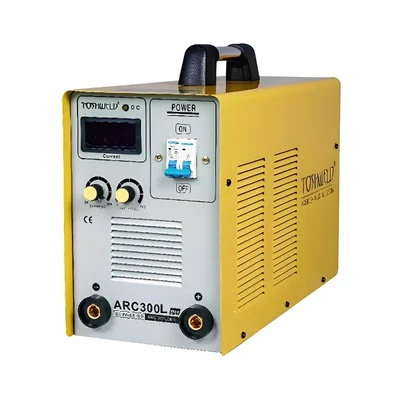

Brand: Toshweld

Toshweld ARC 300 L Single and Double Phase Mosfet Welding Machine, 300 Amp.

SKU: AB-TW-20233241

10 people have bought this recently

10 people have bought this recently  Delivery By: Feb 25 - Feb 27

Delivery By: Feb 25 - Feb 27

MRP : ₹26026 ₹17100

34% OFF!

10 people have bought this recently

10 people have bought this recently  Delivery By: Feb 25 - Feb 27

Delivery By: Feb 25 - Feb 27

Easy Return

& Refund

& Refund

Quality

Assurance

Assurance

Trusted

Delivery

Delivery

After Sales

Assistance

Assistance

Buyer

Protection

Protection

₹17100 (Including GST)

MRP : ₹26026

34% OFF!

Get Extra ₹257 OFF on Prepaid Orders

QTY :

-

1

+

Short Description

ARC 300 L Welding Machine

300 Amp. Welding Machine

Single and Double Phase Welding Machine

Country of origin: India

Specifications

- Brand: Toshweld

- Weight (Approx.) : 10 kg

- Output Current Range : 300 amp

- Technology : MOSFET

- Model No. : ARC 300L

- Input Voltage : AC230V/415V±15%

- Electricity Connection : Single/Double Phase

- Input Power Capacity : 9.4 kVA

- No-Load Voltage : 66 V

- Output Current Range : 20 - 300 Amp

- Rated Input Current : 14.4 Amp

- Power Factor : 0.93

- Plate Thickness : 2.0 – 10.0 mm

- Electrode Size : 2.0 – 4.0 mm

Description

A strong instrument made for demanding welding jobs is a 300 amp welding machine. Because of its high output current capability, it may be used to weld thicker materials and complete tough tasks in a variety of industrial and construction environments. A 300 amp welding machine is a strong and adaptable instrument that can be used by serious enthusiasts as well as professional welders to efficiently complete large tasks.

Features

:- Welding Capability: The toshweld ARC 300 L welding machine can weld a wide range of metals and materials, including steel, stainless steel, cast iron, and other alloys.

- High Amperage Output: The toshweld ARC 300 L welding machine has a high amperage output range of 20-300 amps, making it suitable for welding thick materials and heavy-duty applications.

- Adjustable Amperage Control: The adjustable amperage control allows welders to adjust the welding current to suit the thickness and type of material being welded.

- Inverter Technology: The toshweld ARC 300 L welding machine uses inverter technology, which results in a more stable arc and better welding performance.

- Lightweight and Portable: The toshweld ARC 300 L welding machine is designed to be lightweight and portable, making it easy to move from one job site to another.

- Durable and Reliable: The toshweld ARC 300 L welding machine is built to withstand harsh environments and heavy use, making it a durable and reliable tool for welding professionals.

- Digital Display: The toshweld ARC 300 L welding machine has a digital display that allows welders to monitor the welding process and make adjustments as needed.

Applications

:- Heavy-duty welding

- Maintenance and repair welding

- Fabrication welding

- Construction welding

- Welding of metals and alloys

Safety Precautions :

- Wear Proper Protective Gear

- Use a Well-Ventilated Area

- Keep Flammable Materials Away

- Check for Electrical Hazards

- Keep the Work Area Clean

- Use the Correct Settings

- Disconnect the Power

Note :

- Do not use the welder for work other than welding.

- Do not touch the live part.

- Do not solder in places where skimming, cleaning and spraying are required.

- When using, please wear a protective cover or protective clothing.

Select attribute