- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

- Lab & Measuring Tools

Brand: Ndeal

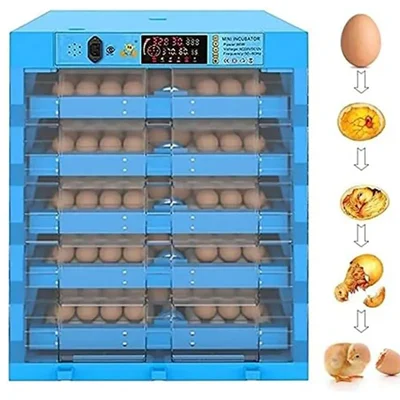

Ndeal 320 Eggs Automatic Egg Incubator, 110/220 V

SKU: TI-AD-12125

23 people have bought this recently

23 people have bought this recently  Delivery By: Feb 25 - Feb 27

Delivery By: Feb 25 - Feb 27

MRP : ₹29195 ₹22195

24% OFF!

23 people have bought this recently

23 people have bought this recently  Delivery By: Feb 25 - Feb 27

Delivery By: Feb 25 - Feb 27

Easy Return

& Refund

& Refund

Quality

Assurance

Assurance

Trusted

Delivery

Delivery

After Sales

Assistance

Assistance

Buyer

Protection

Protection

₹22195 (Including GST)

MRP : ₹29195

24% OFF!

Get Extra ₹333 OFF on Prepaid Orders

Short Description

Automatic Digital Egg Incubator

320 Eggs Capacity

Power Supply Required : 110/220 V

Power Supply Required : 110/220 V

Suitable For Bird Eggs like Hens, Quail, Ducks, etc.

Country of origin: China

Specifications

- Brand: Ndeal

- Weight (Approx.) : 25 kg

- Hatching Ratio : 80-90%

- Operation Grade : Automatic

- Material : ABS Plastic

- Voltage : 110/220 V

- Power Supply : Runs on AC as well as DC current

- Swing Speed : 45o Every 2 Hours

- Time required For chicken Hatching : 21 days

- Time required For duck Hatching : 28 days

- Time required For quail Hatching : 18 days

- Operating Temperature : 37.9 Degree Celsius (Approx.)

- Application : Industrial Purposes & Poultry Farms

- Dimension (L x W x H) : 73 x 53 x 53 cm

Capacity :

- Chicken Eggs : 320 Eggs

- Goose Eggs : 160 Eggs

- Duck Eggs : 213 Eggs

- Quail Birds : 480 eggs.

Description

An egg incubator is a device that creates a regulated environment for eggs to develop and hatch. This is an artificial form of incubation that mimics the conditions required for the development of an embryo, allowing eggs to hatch outside of a mother bird's care. The incubator controls environmental variables such as temperature, humidity, and egg flipping. After the incubation phase, the eggs hatch and chicks or ducklings emerge from their shells.

Features

:- Automatic Temperature Control

- Eggs turn at a 45° swing every 2 hours.

- LED Screen

- It can hatch up to 320 eggs

- In this machine we are using perfect quality components like heating element, high speed fan, temperature controller, ABS Plastic.

- This egg incubator is capable of hatching a variety of bird eggs, including hen, goose, duck, quail, eggs among others.

- Easy and efficient to clean the machine, sealed bottom without messy fall into inside.

- Works on ring heater technology to achieve balanced omnidirectional temperature.

Applications

:- Commercial Hatcheries : In commercial hatcheries, automatic egg incubators play a crucial role in managing large-scale egg production. These facilities rely on the precise control of temperature and humidity to maximize hatching rates and ensure operational efficiency.

- Poultry Farms : Poultry farms utilize automatic egg incubators to incubate eggs from various poultry species, including chickens, ducks, and turkeys. These incubators are designed to accommodate different batch sizes and provide consistent environmental conditions necessary for successful hatching.

- Research and Development : In research settings, automatic egg incubators are essential tools for studying embryonic development and improving breeding techniques. They offer precise environmental controls that are critical for scientific experiments, genetic studies, and advancements in poultry science.

Usage

:- Step 1 : Clean the Incubator : Thoroughly clean and disinfect the incubator to prevent the spread of bacteria and disease.

- Step 2 : Set the Temperature : Set the incubator to the recommended temperature, which is typically around 99.5°F (37.5°C) for chicken eggs.

- Step 3 : Calibrate the Humidity : Humidity levels should be around 40-50% for the first 18 days and 60-70% for the last three days. Use a hygrometer to monitor humidity levels and adjust as necessary.

- Step 4 : Position the Eggs : Place the eggs in the incubator with the larger end slightly upwards. This allows the chick to position itself correctly during hatching.

- Step 5 : Set the Timer for Turning : Automatic incubators should have a setting for egg turning. Set the timer to turn the eggs every two to four hours.

Select attribute