- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

- Lab & Measuring Tools

Brand: Generic ( Made in India )

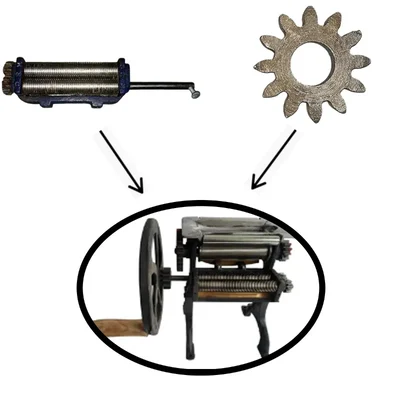

Big Cutter and 12 Teeth Mild Steel Gear(small) Combo for Noodle Making Machines

SKU: TI-BC-62395 Delivery By: Feb 25 - Feb 27

Delivery By: Feb 25 - Feb 27

MRP : ₹3499 ₹3199

9% OFF!

Delivery By: Feb 25 - Feb 27

Delivery By: Feb 25 - Feb 27

Easy Return

& Refund

& Refund

Quality

Assurance

Assurance

Trusted

Delivery

Delivery

After Sales

Assistance

Assistance

Buyer

Protection

Protection

₹3199 (Including GST)

MRP : ₹3499

9% OFF!

Get Extra ₹48 OFF on Prepaid Orders

QTY :

-

1

+

Short Description

Big Cutter & 12 Teeth Mild Steel Gear (small) Combo

For Noodle Making Machines

Country of origin: India

Specifications

- Brand: Generic ( Made in India )

- Weight (Approx.) : 4 kg

- Material : Mild Steel

- Number of Teeth : 12

- Teeth Material : Mild Steel

- Cutter Material : Stainless steel

Description

The Big Cutter and 12-Teeth Mild Steel (MS) Gear Combo is a high-performance replacement and upgrade kit designed for industrial and semi-automatic noodle-making machines. This precision-matched set includes a heavy-duty "Big Cutter" designed for clean, consistent dough shearing and a high-tensile 12-teeth small gear that drives the cutting mechanism with maximum torque. Constructed from industrial-grade Mild Steel, both components are engineered to withstand the high rotational friction and pressure required to process dense wheat dough into various noodle thicknesses. This combo ensures a synchronized movement between the rollers and the cutters, preventing dough clogging and ensuring a smooth, continuous production flow in commercial food processing setups.

Features

:- High-Tensile Mild Steel Construction: Both the cutter and gear are forged from heavy-duty mild steel, offering superior impact resistance and long-term durability.

- Precision 12-Teeth Small Gear: The small gear is engineered with an optimized 12-teeth configuration to provide high torque and perfect synchronization with the main drive.

- Heat-Treated Components: Undergoes a specialized heat-treatment process to increase surface hardness, reducing wear and tear during 24/7 operations.

- Standardized Compatibility: Designed to fit most commercial noodle-making machines, ensuring a hassle-free installation and replacement process.

- Sharp Big Cutter Blades: The cutter features deep-grooved, sharp edges designed to slice through thick dough sheets effortlessly without tearing or sticking.

Applications

:- Commercial Noodle Factories: High-volume production of Chowmein, Hakka noodles, and Ramen.

- Pasta Processing Units: Shaping and cutting various types of pasta and flat noodles.

- Street Food Equipment: Maintaining and repairing portable noodle-making machines used by vendors.

- Food Processing Research: Used in laboratories to test dough consistency and cutting efficiency.

Select attribute