- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

- Lab & Measuring Tools

<

>

Brand: Lab Junction

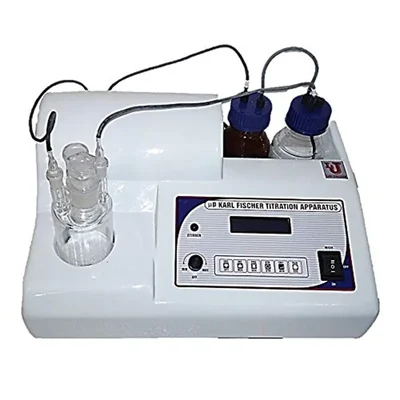

LJ-1760-1 Karl Fischer Microprocessor Moisture Titrator With Alphanumeric LCD

SKU: TI-LK-47029 Delivery By: Feb 26 - Feb 28

Delivery By: Feb 26 - Feb 28

MRP : ₹89500 ₹79400

11% OFF!

Delivery By: Feb 26 - Feb 28

Delivery By: Feb 26 - Feb 28

Easy Return

& Refund

& Refund

Quality

Assurance

Assurance

Trusted

Delivery

Delivery

After Sales

Assistance

Assistance

Buyer

Protection

Protection

₹79400 (Including GST)

MRP : ₹89500

11% OFF!

Get Extra ₹1,191 OFF on Prepaid Orders

QTY :

-

1

+

Short Description

LJ-1760-1 Karl Fischer Microprocessor Moisture Titrator

With 16 x 2 Alphanumeric LCD

Country of origin: India

Specifications

- Brand: Lab Junction

- Model: LJ-1760-1

- Measuring Range: 100ppm to 100% of moisture

- Measuring Method : Karl Fischer Volumetric Titration Method

- K.F Dispensing : Highly Sensitive motorized dispensing system

- Resolution of titrant volume: 0.01 ml

- Indication of Titrant volume: 0.00 to 99.99ml on display.

- End Point Alarm: Visual LED and Audible alarm

- Dispensing Pump Calibration: Available through Keyboard.

- Wait time for point end: Adjustable( 1 to 59 seconds)

- Key board: 6 keys soft touch membrane type

- Data storage(K.F consumed) : with date and time.

- Display: 16 x 2 Alphanumeric LCD with backlit

- Clock: In built clock with date and time display.

- Stirrer: In built magnetic stirrer with adjustable speed

- Reagent bottle: 3x 250 ml bottle for K.F Reagent, methanol and calcium chloride.

- Printer Interface: External Serial printer interface available

- Power Supply: 230V AC ± 10% 50 Hz

- Dimensions: 360 x 295 x 175 mm

Description

Lab Junction's Microprocessor K.F. Moisture Titrator LJ-1760-1 is the finest volumetric titrator available. It uses the latest microcontroller technology and advanced engineering techniques so as to give enhanced accuracy and reproducibility. The system has user friendly prompts which guide you throughout the titration process. This titrator eliminates the use of conventional delicate and fragile glass burettes and plunger systems. It uses a highly sensitive motorized dispensing system for precise control of titrant volumes. This titrator analyses the moisture concentration of liquid samples, powder, fine particles and fiber samples that are soluble in alcohol or solvents.

The system has 6 soft touch membrane type keys for ease of operation. The End Point indication is given by both visual LED and audible alarm. It has the storage facility of date, time, batch no. of 20 titrations using the FIFO method. The internal battery backup; provision has been made to store the results and the other titration parameters for a minimum of 1 month even if the instrument is not switched ON. Provision for external printer attachment is available so that any of the stored results can be printed even at a later stage.

Features

:- Storage of Date, Time, Batch No.

- 16 x 2 with Alphanumeric LCD with Backlit

- Motorized Dispensing

- External Printer Attachment Facility

Accessories

:- Dual Platinum Electrode

- Built-In Magnetic Stirrer

- 250ml Bottle for Methanol

- 10 Syringe

- Adapter for K.F. Reservoir

- Set of Dispenser Tubes

- Bottle Container

- Dust Cover

- Titration Vessel with Teflon Cover

- Teflon Coated Magnetic Stirring Capsule

- 250 ml Reservoir Bottle for K.F. Solution

- 250 ml bottle for Calcium Chloride Methanol Reservoir Bottle

- Set of Connecting Tubes

- Main Lead

- Instruction Manual

Applications

:- Pharmaceuticals: To check moisture in raw materials, powders, and finished drugs.

- Petrochemicals: To measure water in oils, fuels, and lubricants.

- Food industry: For testing moisture in ingredients and processed foods.

- Chemicals and plastics: To ensure correct composition and prevent degradation due to water.

- Electronics: To verify dryness of materials like solvents and resins.

Select attribute