- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

- Lab & Measuring Tools

<

>

Brand: Generic ( Made in India )

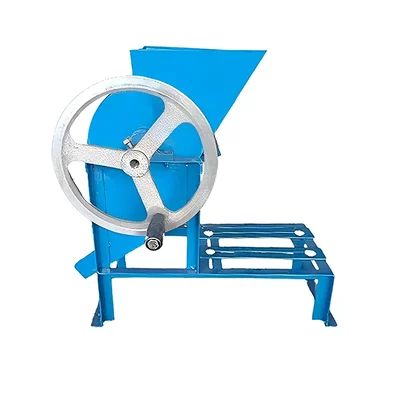

Made in India Manual Peanut Shelling/Decorticator Machine, 50 Kg/Hr

SKU: RON-UNI-200358

371 people have bought this recently

371 people have bought this recently  Delivery By: Feb 6 - Feb 8

Delivery By: Feb 6 - Feb 8

MRP : ₹3699 ₹3419

8% OFF!

371 people have bought this recently

371 people have bought this recently  Delivery By: Feb 6 - Feb 8

Delivery By: Feb 6 - Feb 8

Easy Return

& Refund

& Refund

Quality

Assurance

Assurance

Trusted

Delivery

Delivery

After Sales

Assistance

Assistance

Buyer

Protection

Protection

₹3419 (Including GST)

MRP : ₹3699

8% OFF!

Get Extra ₹51 OFF on Prepaid Orders

QTY :

-

1

+

Short Description

Made in India Manual Peanut Sheller/Decorticator

Used for de-husking peanut and groundnut

Production Capacity 50 Kg Per Hour

Mild Steel Material

Country of origin: India

Specifications

- Brand: Generic ( Made in India )

- Weight (Approx.) : 11 kg

- Material : Mild Steel

- Production Capacity : 50 Kg Per Hour

- Automation Grade : Manual

- Surface Treatment : Paint Coated

- Dimension (L x B x H) : 20 x 9 x 21 inches (50.8 x 22.86 x 53.34 cm)

Notes :

- Color may vary.

- Product dimension may vary.

Description

The manual peanut shelling machine is a mechanical device designed to efficiently remove shells from peanuts through a simplified, labor-intensive process. Constructed with durability in mind, it typically features a robust frame made of metal or high-grade plastic, with an integrated mechanism that utilizes leverage and rotating components to separate the kernels from their shells. Operated by hand, the machine allows users to feed peanuts into an entry funnel, where they are subsequently shelled by the action of the device. This machine not only enhances productivity but also minimizes damage to the delicate peanut kernels, making it an essential tool in small-scale agricultural settings.

Features

:- Easy to Use: The machine operates manually, making it user-friendly for individuals of various age groups and skill levels. Its straightforward operation allows anyone to efficiently process peanuts without the need for specialized training.

- Compact & Portable: The manual peanut sheller is lightweight and compact, making it easy to store when not in use. This portability is particularly beneficial for farmers or small business owners who may have limited space.

- High Efficiency: The manual peanut sheller is designed to quickly de-shell large quantities of peanuts with minimal effort. It can shell approximately 50 kg of peanuts per hour.

Applications

:- Snack Production: They are commonly used by small-scale snack manufacturers who produce roasted peanuts or nut mixes.

- Confectionery Manufacturing: In candy production, shelled peanuts are often incorporated into products like peanut brittle or chocolate-covered peanuts.

- Nut Butter Production: Before grinding peanuts into butter, it is essential to remove the shells; thus, these machines play a crucial role in preparing raw materials.

- Culinary Uses at Home: Individuals may also use manual peanut shellers at home for personal cooking needs, especially when preparing traditional dishes that require shelled peanuts.

Usage

:1. Preparation:

Before using the manual peanut shelling machine, it is essential to prepare adequately:

- Clean the Machine: Ensure that the machine is clean and free from any debris or leftover peanuts from previous uses.

- Inspect for Damage: Check for any signs of wear or damage that could affect performance. Look at the moving parts, hoppers, and shelling mechanisms.

- Read the Manual: Familiarize yourself with the operating manual provided by the manufacturer to understand specific features and safety precautions.

2. Loading Peanuts:

Once prepared, you can load peanuts into the machine:

- Feed Peanuts Evenly: Pour a manageable amount of peanuts into the feeding hopper or tray. Avoid overloading as this can hinder performance.

- Ensure Uniform Distribution: Make sure that peanuts are evenly distributed in the hopper for consistent shelling.

3. Operating the Machine:

With everything set up, you can now operate the machine:

- Start Shelling Process: Begin turning the handle or activating any manual mechanism designed for shelling. The action should be steady and consistent.

- Monitor Performance: Keep an eye on how well peanuts are being shelled. If you notice any issues such as clogging or uneven shelling, stop and make necessary adjustments.

4. Collecting Shelled Peanuts:

After processing, collect your shelled peanuts:

- Separate Shells from Kernels: The shells should be expelled from one side while kernels fall into a designated container.

- Check Quality: Inspect shelled peanuts for quality and ensure that most shells have been removed.

Maintenance:

- Regular Cleaning: Cleaning is fundamental to the maintenance of both the peanut shelling machine and the grader. Remove any leftover peanuts, shells, and debris from both machines. Ensure that all parts are free from dirt and residue that could lead to clogs or mechanical issues.

- Pre-operational Inspections: Check the blades, bearings, seals, and other components for signs of wear or damage. Look for any loose parts or connections that may have occurred due to vibrations during previous operations.

Select attribute