- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

- Lab & Measuring Tools

Brand: Generic (Imported)

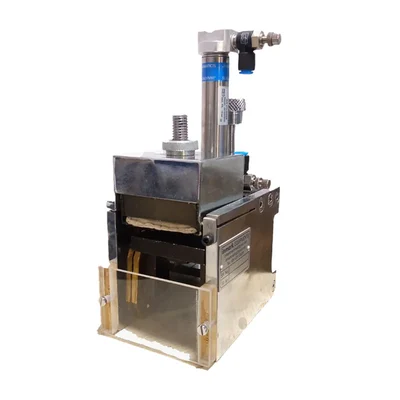

Commercial MS Plated Pneumatic Batch Printing Machine

SKU: TI-CM-11518 Delivery By: Feb 26 - Feb 28

Delivery By: Feb 26 - Feb 28

MRP : ₹15200

Delivery By: Feb 26 - Feb 28

Delivery By: Feb 26 - Feb 28

Easy Return

& Refund

& Refund

Quality

Assurance

Assurance

Trusted

Delivery

Delivery

After Sales

Assistance

Assistance

Buyer

Protection

Protection

₹15200 (Including GST)

Get Extra ₹228 OFF on Prepaid Orders

Short Description

Pneumatic Batch Printing Machine

30 mm x 50 mm Printing Area

30 mm x 50 mm Printing Area

MS Plated Material

Country of origin: China

Specifications

- Brand: Generic (Imported)

- Weight (Approx.) : 5 kg

- Automation Type : Semi-Automatic

- Material : MS Plated

- Printing Area : 30 mm x 50 mm

- Genetic Cylinder : 30x40 Stroke

Description

This MS Plated Pneumatic Batch Printing Machine is a specialized printing device designed for high-speed and efficient batch coding applications, particularly in industrial settings. This machine utilizes pneumatic technology, which means it operates using compressed air to facilitate the printing process.

Features

:- Fast printing machine

- Smooth printing

- Easy to use

- Durable

- Easy to move from one place to another.

Accessories

:- Felt Pad

- 250 ml Ink

Usage

:- Setup the Machine : Place the machine on a stable surface. Ensure that all components are securely attached and that the pneumatic system is connected to a suitable air source.

- Load the Ink : Open the ink reservoir and fill it with the appropriate ink for your printing needs.

- Adjust Printing Settings : Set the desired settings using the control panel. Adjust the print height according to the thickness of the material being printed.

- Prepare Printing Material : Position your product or packaging material under the printing head. Ensure that it is aligned correctly to receive an accurate print.

- Start Production : Begin batch printing by activating the machine. Monitor the operation for any issues such as ink flow or misalignment.

Maintenance :

- After completing your printing tasks, clean the printing head and other components as per manufacturer instructions to prevent clogging and ensure longevity.

Applications

:- Food and Beverage Industry : Printing on labels, cartons, and pouches to ensure compliance with labeling regulations.

- Pharmaceuticals : Marking critical information on medicine packaging to maintain traceability and safety.

- Cosmetics : Applying batch numbers and expiry dates on cosmetic products to inform consumers.

- Manufacturing : Used in factories for marking products directly during the production process on surfaces like metal, plastic, or cardboard.

Select attribute