- Farm & Garden

- Pumps & Motors

- Food Processing

- Workshop, DIY & MRO

- Lab & Measuring Tools

<

>

Brand: Generic (Imported)

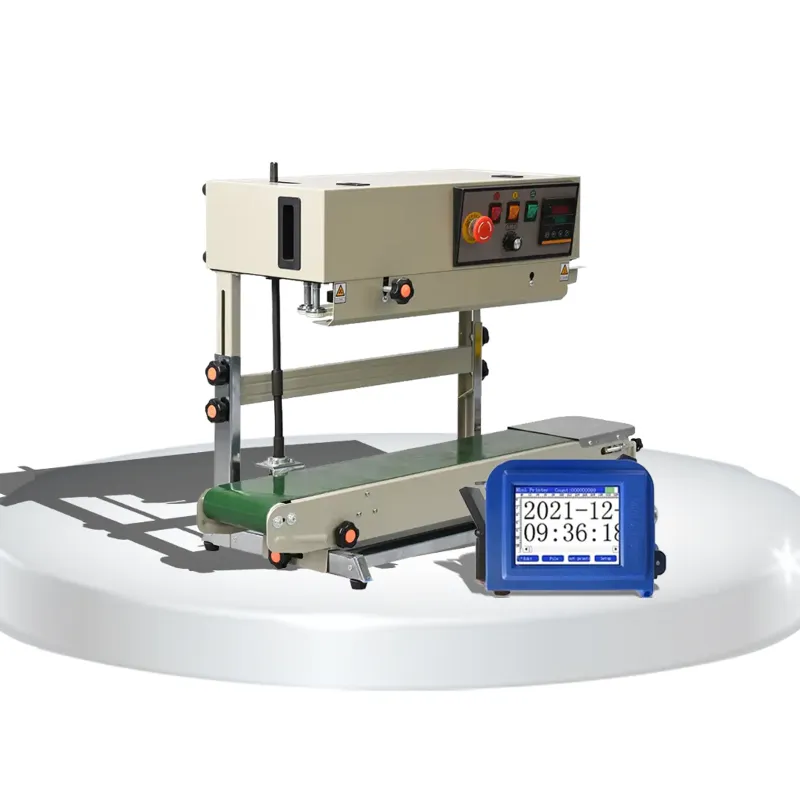

COMBO of Heavy Duty MS Vertical FR-900 Band Sealer with Ink Coding Printer & Free Accessories

SKU: DM-MM-20234995

4111 people have viewed this recently

4111 people have viewed this recently  Delivery By: Feb 26 - Feb 28

Delivery By: Feb 26 - Feb 28

MRP : ₹26000 ₹21999

15% OFF!

4111 people have viewed this recently

4111 people have viewed this recently  Delivery By: Feb 26 - Feb 28

Delivery By: Feb 26 - Feb 28

Easy Return

& Refund

& Refund

Quality

Assurance

Assurance

Trusted

Delivery

Delivery

After Sales

Assistance

Assistance

Buyer

Protection

Protection

₹21999 (Including GST)

MRP : ₹26000

15% OFF!

Get Extra ₹330 OFF on Prepaid Orders

QTY :

-

1

+

Short Description

Combo Pack of Band Sealer and Coding Printer Machine

Band Sealer Power 500 W and Band Sealer Sealing Speed 0-12 m/min

Coding Machine Cartridge Type 12.7 mm Coding Machine Printing Distance 2-5mm

Band Sealer Power 500 W and Band Sealer Sealing Speed 0-12 m/min

Coding Machine Cartridge Type 12.7 mm Coding Machine Printing Distance 2-5mm

Country of origin: China

Specifications

- Brand: Generic (Imported)

- Weight (Approx.) : 20 kg

Product type : Band Sealer

Product type : Coding Machine

Note :

- Material : Mild Steel

- Controller Type : Digital

- Running Time : 8 to 10 hours. (Non Stop)

- Voltage : 220 V

- Frequency : 50 Hz

- Power : 500 W

- Sealing Speed : 0-12 m/min

- Sealing Width : 6-12 mm

- Height Adjustment : 14 inch Max (Approx)

- Temperature Range : 0-300°C

- Max. Conveyor Loading : 4 kg (Approx)

- Dimension (L x W x H) : 860 x 370 x 320 mm

- Product Weight of Band Sealer : 20 Kg (Approx.)

- Power input : DC-9V/2A

- Power Rating : 25 Watt

- Cartridge Type : 12.7 mm

- Power Supply Mode : Fast charge 3.0 adapter

- Print Resolution : 600 dpi (Maximum)

- Printing Distance : 2-5mm

- Language : Chinese, English

- Print content : Time, Date, Counter, QR code, Bar code, LOGO

- Print media : Boards, Carton, Pipe, Cable, Metal, Plastic, Concave convex surface

- Dimensions (L x W x H) : 97 x 70 x 45 mm

- Product Weight : 1 Kg (Approx.)

Note :

- Conveyor belt color may vary.

- If you make full online payment on this product then you will get instant discount on your purchase

- Suitable for High Graded Pouches, just like laminated Pouches.

Description

This continuous band sealer can seal high graded pouches continuously. This continuous band sealer machine is easy to operate and also suitable for sealing small packages in foodstuffs, general merchandise, medicine, spices, seeds, and chemical industries. This band sealer and the mini-coding printer are made of high-quality materials, ensuring durability and extending machine life. Mini-inkjet coding is used for batch numbers, date coding, and exp date coding. You can use the coding machine for printing on labels, pouches, and carton boxes. These two machines are among the top combo goods.

Features

:- Premium heavy duty machine.

- Easy to operate

- Fast packing machine

- Time saver

- Different types of high graded pouches can be sealed

- This coding machine can print dates, bar codes and etc.

Accessories

:- 2 Pcs (15 X 750 mm)Size Teflon Belt

- 2 Pcs Teethed Timing Belt

- Screw Driver

- Power Cable

- Chabi/Simple Rinch

- Printer Machine

- 1 USB C Cable

- 1 Adaptor

- 1 Ink Cartridge

How to Use Band Sealer :

Setup :

- Ensure the machine is placed on a stable surface.

- Connect the sealer to a power source and turn it on.

Temperature & Speed Settings :

- Adjust the temperature control based on the material you are sealing.

- Set the sealing speed depending on the production requirements.

Loading the Pouch :

- Place the open end of the pouch or bag containing the product on the sealing conveyor belt.

- Ensure the bag is aligned properly for sealing.

Start Sealing :

- Activate the sealer by pressing the start button.

- As the bag moves through the sealing area, the heated band will seal it along the edge.

Cooling :

- Once sealed, the bag will pass through a cooling section to solidify the seal.

- Ensure the seal is intact and check for any potential defects.

Remove the Sealed Bag :

- After sealing, carefully remove the bag from the conveyor and inspect for a strong, consistent seal.

How to Use Coding Printer :

- Check the Printer : Before using the mini inkjet coding machine, ensure it is clean.

- Edit the Batch Code : Once you confirm that the printer is functioning properly, edit your desired text, date, or numbers in the software.

- Position for Printing : Move the nozzle to the specific location where you want to print the batch code on your product.

- Print the Batch Code : Press the printing button to print the code onto your product.

- Post Printing Process : After printing, remove the ink cartridge from the printer and store it in its protective cover to prevent drying out of the nozzle.

Maintenance :

- Clean Regularly the Band Sealer : Wipe down the sealing area, conveyor belt, and sealing jaws after each use to remove product residue, dust, or debris.

- Clean Print Head of the printer : Regularly clean the print head using a soft cloth and appropriate cleaner to avoid ink blockages and ensure clear, crisp prints.

- Inspect Electrical Connections : Periodically check power connections and wiring for any signs of damage or wear.

Applications

:- Food Industry : Seals bags containing chips, nuts, candies, and other snack products.

- Pharmaceutical Industry : Seals packaging for tablets, capsules, syrups, and other medical supplies.

- Cosmetics and Personal Care : Seals pouches or bags containing skincare products, lotions, and shampoos.

- E-Commerce and Retail : Seals bags containing retail goods like toys, clothing, electronics, or accessories.

Select attribute